Advantages of Using Extrusion Blow Molding for Large Volumes

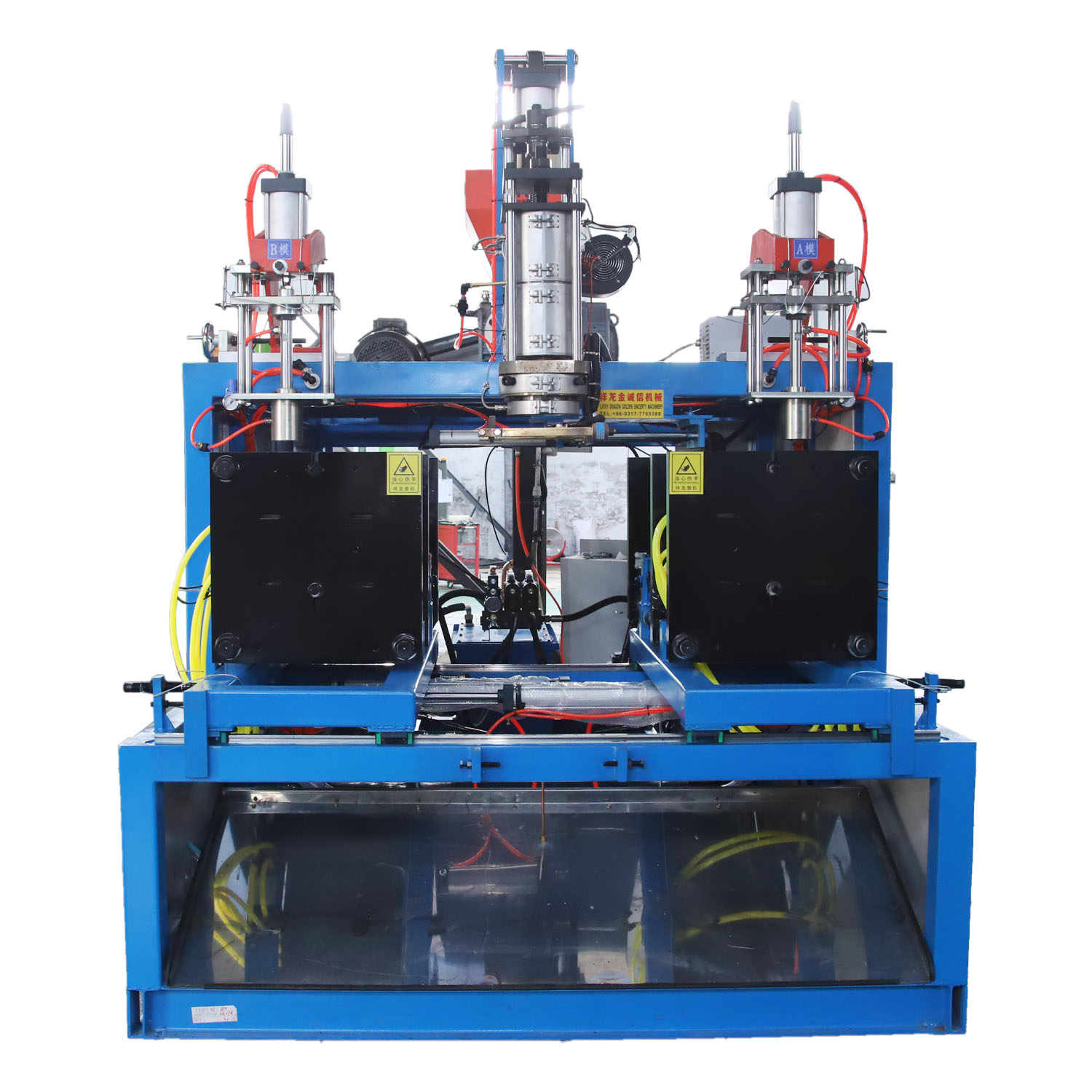

A perfect example of this type of manufacturing is extrusion blow molding, which makes it possible to produce large hollow plastic parts in mass and in a repetitive and consistent manner. It uses plastic parts, melts them, and then injects them into a mold, inflating them to take the shape of the mold. This method yields parts non-stop and in bulk, thus allowing getting a significant amount during each production cycle. This is most advantageous for the packaging industry, automotive industry, and consumer goods manufacturing, where consistent and uniform parts are essential for meeting production targets. Further, other non-stop production processes can greatly benefit from it.

Cost Effectiveness for Mass Production

With extrusion blow molding, in mass production of plastic parts, the cost of production of each piece is greatly reduced. This is achieved because plastic parts are melted into uniform shapes, meaning that uniform and repeatable parts are melted in bulk. Each shape is filled with a blow cycle which makes the bloat non-stop and in bulk. Getting parts to maintain the shape of the mold also results in non-stop return of the mold-less parts. Further, due to low maintenance of the shape molds, these can be reused for quite a number of cycles. All of this leads to minimal plastic waste, reduced labor cost and therefore, in unmatched low cost of production.

Flexibility in Product Design

The extrusion blow molding process is ideal for creating containers, bottles, and tanks because it handles a vast array of sizes and shapes with ease. The complexity of the hollow shapes it is able to create is in fact, intricate. In addition, the process allows the thickness of the walls to be controlled so they can be stronger or lighter based on the application. In addition, branding or functional design elements can be incorporated into the mold which allows the product to require little to no work after it is done being produced.

Strength and Consistent Quality

Quality and strength are consistent for each unit, which is a major benefit for businesses that regularly order stock. Every piece produced is identical and this is critical for industries that have to meet stringent requirements for safety and performance. The extrusion blow molding process is able to manufacture seamless walls that are incredibly resilient to pressure, impacts, and extreme temperatures which makes them ideal for harsh conditions.

Meeting the Growing Needs of a Business

Meeting the everchanging requirements of a growing business is another advantage that extrusion blow molding processes offer. Increased production requirements can be met efficiently and rapidly while maintaining the same quality. The molding is a great solution for businesses that need to meet a quick turnaround or deal with large order volumes.