Choosing the Right Plastic Blow Molding Machine for Your Product Line

A plastic blow molding machine plays a key role in turning plastic pellets into hollow products that fit various markets. By first heating plastic and then blowing it into a cooled mold, these machines can quickly generate bottles, large tanks, and a wide range of other hollow goods. For manufacturers of packaging or industrial products, picking the right system isn’t just a purchase—it’s a business choice that shapes both the final product and the speeds the factory can achieve.

Types of Plastic Blow Molding Machines

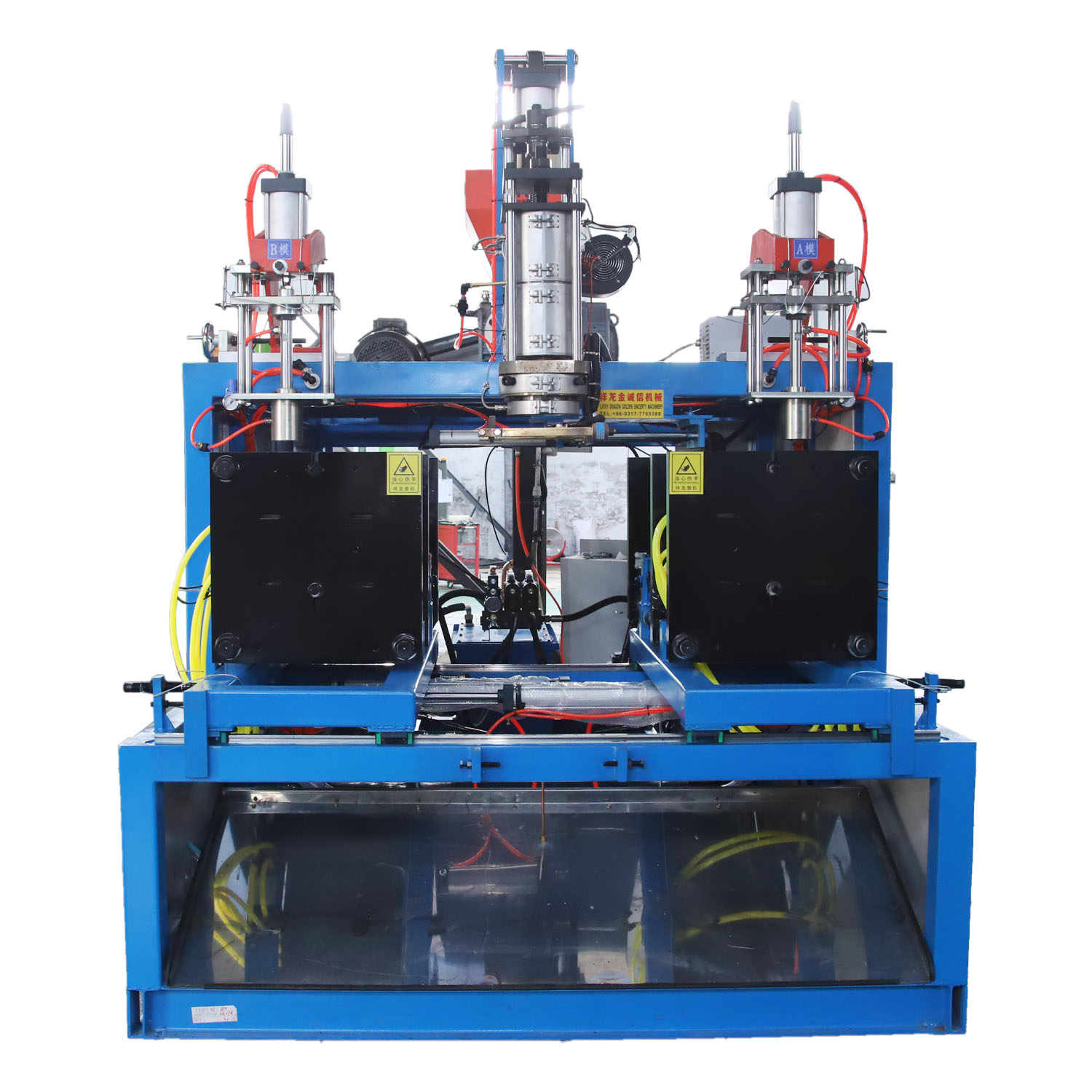

The market offers three prominent families of blow molding machines, each engineered for specific tasks. **Extrusion blow molding machines** typically make bottles or larger shapes by forcing a continuous parison of molten plastic. **Injection blow molding machines** create precision items like pharmaceutical bottles, where a precise neck and wall thickness give a consistent shape. **Stretch blow molding machines** stretch and blow preforms mostly for the beverage sector, especially in PET applications where high clarity and wall strength are essential. Understanding the core capability of each type ensures that firms invest in the technology that delivers the best combination of quality and speed for their end product.

Key Factors to Consider

Choosing a plastic blow molding machine starts with understanding your production volume. High-speed, fully automated systems are ideal for big, nonstop production lines. Smaller machines work best for specialized parts or orders that are lower in quantity. You should also check which raw materials the machine can reliably process. Since not every plastic melts or cools the same way, the machine must fit the formulation well. Other important points are how much energy the machine consumes, how often you’ll need to maintain it, and how easy it is for operators to work with day after day.

Matching Machines with Product Requirements

Each product carries specific specs like how thick the walls should be and how even the shape needs to be. A good machine is the one that can fulfill those specs without delivering second-best parts. For instance, a plant that makes food-safe bottles must buy machines that meet cleanliness rules and can make every bottle the same size, batch after batch. Conversely, a site molding big storage tanks should look for machines that apply stronger clamping pressure and that can use different molds without much hassle. Choosing right means cutting waste, raising the quality of every item, and driving profit for the long haul.

Working with a Reliable Supplier

Picking the right machine is only part of the job; the supplier matters just as much. A dependable partner doesn’t just sell you a machine—they back the sale with hands-on technical coaching, spare parts, and same-day repair services. That’s how you keep production moving and downtime short. JKing Machine is a good example. They specialize in blow molding setups and work alongside you to slot the right equipment into your production floor. Their expertise means fewer headaches and more reliable output, which is a big plus when you’re ramping up capacity and chasing the same quality with more volume.

Conclusion

Buying a blow molding machine is only a first step; the real win is how the right choice supports lasting growth. Look at your current production rate, the kind of resin you use, whether you need standard or custom parts, and the level of support the seller provides. Knit in these factors and you’ll find a machine that slashes cycle times, keeps costs in check, and delivers products with the quality your customers rely on, setting you up to stay a step ahead in a crowded marketplace.