How does a blow molding machine improve production efficiency?

Why is the blow molding machine worth investing in?

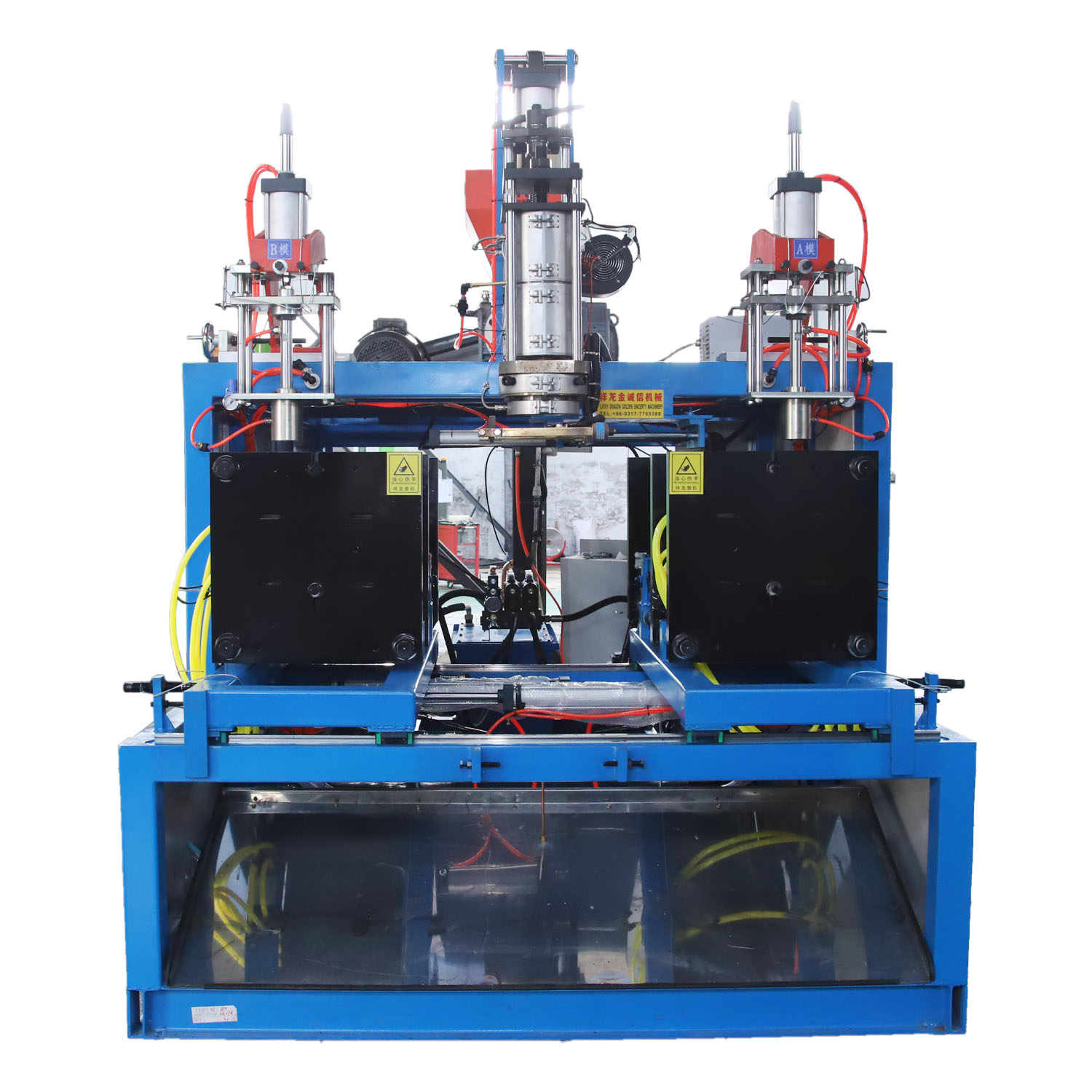

In any manufacturing industry, the blow molding machine has become a vital piece of equipment for making plastic containers, bottles, and other hollow items with an ease and speed. The machines are a favorite among manufacturers not only for the seamless end products they produce but also for the speed and efficiency at which the machines are able to operate. This blog is geared towards understanding some of the reasons machinery increases efficiency on production lines.

Streamlined Work Sets

From raw materials feeding, to the finished product being ejected, “smart” blow molding machines have “automated” systems, which reduce the levels of direct human interactions, Straightening work processes also increases productivity. Over a hectare of land, the machine can simultaneously “feed” materials, which in turn increases productivity. For instance, materials “feed” the machines in a orderly and controlled manner due to automated systems. This increases the speed, which maximizes the machine uptime; in turn, maximizing the production and yield.

Reduced Maintenance and Servicing Outages

Last and the most critical characteristic of blow molding machines which separates them from the rest of the molding machines is the speed at which each cycle takes. The advanced systems in bolw molding machines are designed to melt the plastic, form a parison, cool, and finalize the product in. The advanced systems in new machines require a fraction of the time it takes for each step with new cooling and heating components.

Compared to older methods of manufacturing, having shorter cycle times will improve output, whether on a daily or hourly basis, to a much greater extent than slower manufacturing methods.

Precision and Consistency

Defective products are minimized because blow molding machines are built to produce products with high precision, along with consistent wall thickness, shape, and size. This means that less records are wasted, and production lines do not slow down to manage rejections or reworks on defective products. This also means that streamlining and simplifying cross-checks with quality control becomes effortless, thus increasing output while saving time.

Versatility in Production

There is no longer a need to purchase additional machines in factories, along with having to travel and set them for multiple products, because of the machines’ capability to use different materials and shapes. Also, the machines’ rest period is less than a minute, since some operations like adjusting the molds can be completed in a short time. This is also referred to as quick changeover features.

Energy Efficiency

Modern blow molding machines are built with energy-saving technologies.

Theres a decrease in energy use for the motors and cooling systems, which positively impacts costs. Savings and a sustainable machine translated to continuous operation, with no overheating or needing frequent breaks. This, in turn, maximized productivity for the rest of the day.

Less plastic waste lowers the costs of raw materials, and reduces time spent on waste management. Allaging materials such as molding plastic which imperfects with scrapped or defective products, can be reused or repurposed, generally improving waste management.

To sum up, lower production costs and improved efficiency from automation lead to improved cycle times. Less time spent on intricate steps of the process ensures that the manufacturing lines produce high-quality, market-ready products. With advancing technology, we can further refine the efficiency of blow molding machines for improved performance in the manufacturing sector.