How to select plastic blow molding machine for food packaging?

Time : 2025-12-19

Prioritize food grade safety compliance

When choosing a plastic blow molding machine for food packaging, safety compliance is the top priority. The machine must be able to produce products that meet food contact safety standards. First, check if the plastic blow molding machine uses food grade materials for its contact parts such as molds and extrusion components. These parts should not release harmful substances that could contaminate food. Reputable manufacturers with over 20 years of blow molding experience usually adhere to strict quality control, ensuring their plastic blow molding machines meet international food safety regulations. Additionally, the production process of the plastic blow molding machine should be clean and free of pollution. Look for machines with closed production systems to prevent dust or other impurities from entering the products. Some advanced plastic blow molding machines also have automatic cleaning functions, which help maintain a hygienic production environment. Choosing a machine that complies with food grade safety requirements is the foundation for producing qualified food packaging.

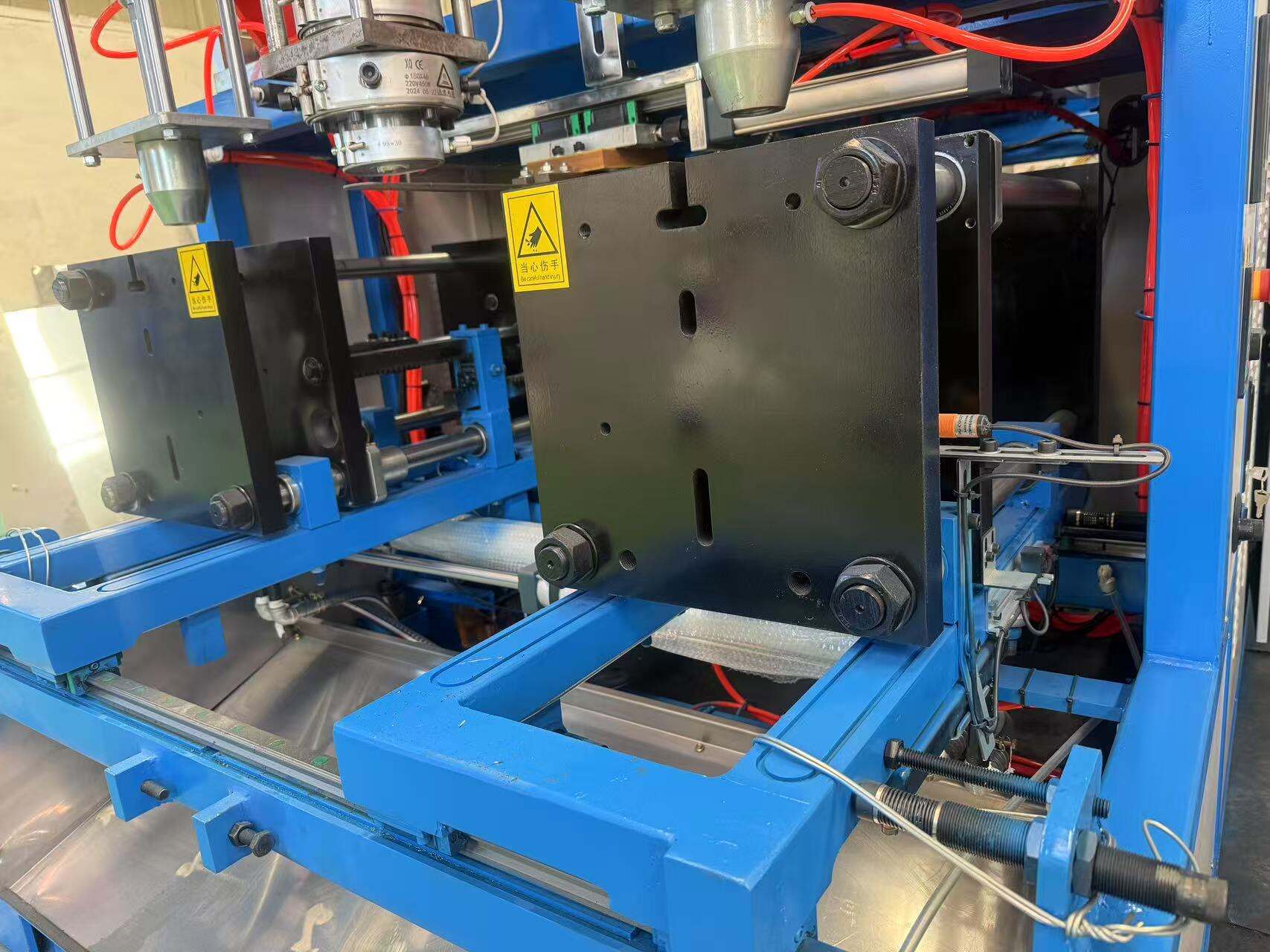

Focus on production precision and product consistency

Food packaging requires uniform thickness, smooth surfaces and consistent shapes to ensure sealing performance and product appearance. Therefore, the production precision and product consistency of the plastic blow molding machine are crucial factors. Opt for a plastic blow molding machine equipped with advanced technologies like electric clamping and electric mold shifting. These patented technologies can significantly improve the machine's operational accuracy, ensuring that each food packaging product has the same specifications. The machine's extrusion system should also be stable, providing a continuous and uniform parison to avoid uneven thickness of the finished products. Manufacturers with strong technical teams often optimize the design of the plastic blow molding machine to enhance its stability. You can also ask for sample products from the manufacturer to check their consistency. A plastic blow molding machine with high precision and good consistency can reduce product defects and ensure the quality of food packaging.

Consider production capacity matching market demand

The production capacity of the plastic blow molding machine should align with your market demand and production scale. If you are a large food enterprise with high daily output requirements, a fully automatic plastic blow molding machine is a better choice. It can realize continuous production from material feeding to finished product output, with high production efficiency and low manual intervention. For small and medium sized enterprises or those with small batch production needs, a semi automatic plastic blow molding machine may be more cost effective. It can meet the production demand while controlling investment costs. When selecting, you should also consider the flexibility of the plastic blow molding machine. Some machines can produce food packaging of different sizes and shapes by changing molds, which is suitable for enterprises that need to produce multiple types of products. Understanding your own production needs and choosing a plastic blow molding machine with matching capacity can avoid resource waste or insufficient supply.

Evaluate energy efficiency and cost effectiveness

Energy efficiency and cost effectiveness are important practical factors when selecting a plastic blow molding machine for food packaging. A energy efficient plastic blow molding machine can reduce production costs. Look for machines that adopt energy saving technologies such as hydraulic servo systems, which can reduce energy consumption by a certain percentage while ensuring production efficiency. In addition to energy consumption, you should also consider the overall cost of the plastic blow molding machine, including purchase price, maintenance costs and spare parts replacement costs. Manufacturers that offer factory direct sales often provide more competitive prices. At the same time, high quality plastic blow molding machines have stable performance and long service life, reducing the frequency of maintenance and replacement. You should also pay attention to the material utilization rate of the machine. A machine with high material utilization rate can reduce waste and save raw material costs. Considering these factors comprehensively can help you select a cost effective plastic blow molding machine.

Check after sale service and technical support

Reliable after sale service and technical support are essential for the long term stable operation of the plastic blow molding machine. Food packaging production has high requirements for continuity, so any machine failure can cause significant losses. Choose manufacturers that provide comprehensive pre sale, sale and after sale services. They should offer professional consultation before purchase to help you select the most suitable plastic blow molding machine. After purchase, they should provide timely maintenance and repair services, as well as quick supply of spare parts. Manufacturers with strong technical teams can also provide technical training for your operators, helping them master the use and maintenance skills of the plastic blow molding machine. Some manufacturers even offer online video tours and one on one personalized services to solve problems for customers in a timely manner. Good after sale service and technical support can ensure that your production is not affected by machine problems, and maximize the service life of the plastic blow molding machine.