How to ensure stable performance of HDPE blow molding machine?

Time : 2025-12-05

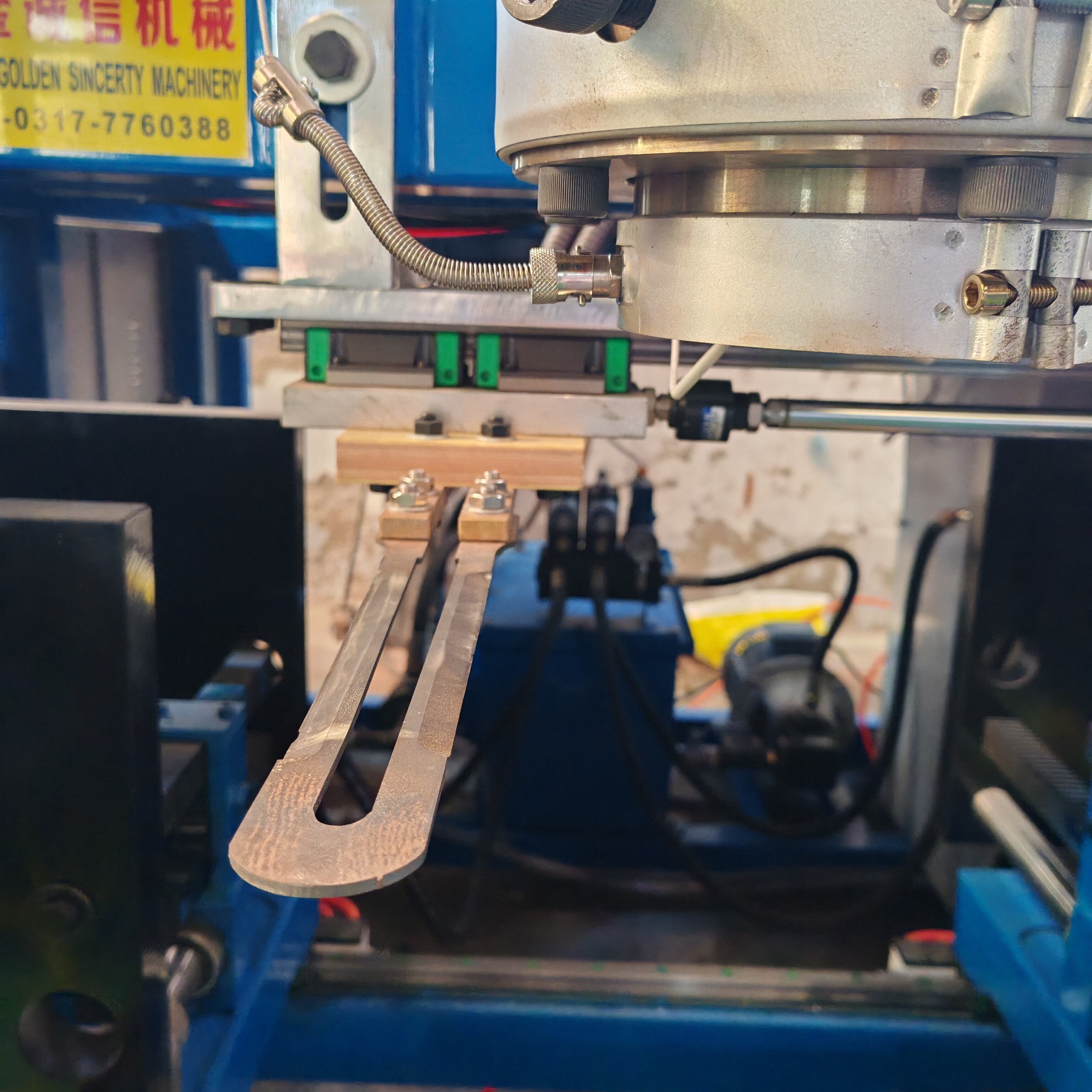

Choose a high quality HDPE blow molding machine from reliable manufacturers

The foundation of stable performance lies in selecting a quality HDPE blow molding machine. You should opt for manufacturers with rich experience and strong technical strength. Look for those with over 20 years of blow molding experience, as they have honed their craft through years of practice. These manufacturers usually have professional technology teams that continuously optimize the machine design. A well designed HDPE blow molding machine has reasonable structure and beautiful appearance, which lays a solid foundation for stable operation. Also, check if the machine has relevant technical patents, such as electric clamping or electric mold shifting technologies. These patented technologies can greatly improve the precision and stability of the HDPE blow molding machine. Moreover, manufacturers that offer factory direct sales often provide better quality control, ensuring the HDPE blow molding machine you get is of high quality at a reasonable price. Cooperating with such reliable manufacturers also means you can enjoy comprehensive pre sale, sale and after sale services, which is crucial for long term stable use of the machine.

Do proper pre operation inspection and preparation

Before starting the HDPE blow molding machine, thorough inspection and preparation are essential to avoid malfunctions during operation. First, check the key components of the HDPE blow molding machine, such as the mold, clamping system and extrusion system. Ensure the mold is clean and free of debris, and that the clamping system is tightly secured without looseness. Then, verify the material quality. Use HDPE materials that meet the production requirements, as inferior materials can affect both product quality and machine stability. Check if the material is dry and free of moisture, which could cause bubbles or defects in the finished products and put extra load on the machine. Additionally, set the correct operating parameters according to the product specifications. Adjust the temperature, pressure and speed reasonably to match the requirements of the HDPE blow molding machine and the production task. Proper pre operation preparation can effectively prevent unexpected problems and ensure the HDPE blow molding machine runs smoothly from the start.

Follow standard operating procedures during production

Standard operation is a key factor in maintaining the stable performance of the HDPE blow molding machine. Operators should be trained professionally and familiar with the machine's working principle and operating steps. During production, strictly follow the prescribed procedures to avoid arbitrary adjustments to parameters. For example, do not change the temperature or pressure settings randomly while the machine is running, as this can disrupt the stable operation of the HDPE blow molding machine and lead to product defects or machine damage. Pay close attention to the machine's operation status in real time. Observe the extrusion speed, clamping force and product forming effect. If any abnormalities are found, such as unusual noises or uneven product thickness, stop the machine immediately for inspection and troubleshooting. Avoid overloading the HDPE blow molding machine. Arrange the production task reasonably according to the machine's rated capacity. Continuous overloading will accelerate the wear of parts and affect the machine's stability and service life.

Conduct regular maintenance and upkeep

Regular maintenance is vital to keep the HDPE blow molding machine in stable working condition for a long time. Establish a detailed maintenance plan and carry it out on a regular basis. Clean the machine after each shift to remove plastic residues and dust from the surface and internal components. This prevents debris from accumulating and affecting the machine's movement. Check the lubrication of moving parts regularly and add or replace lubricating oil as needed. Good lubrication can reduce friction between parts, lower energy consumption and extend the service life of the HDPE blow molding machine. Inspect easily worn parts such as the mold and cylinder needle periodically. Replace damaged or worn parts in a timely manner to avoid affecting the overall performance of the machine. Also, conduct regular comprehensive inspections of the electrical system and hydraulic system to ensure all connections are tight and there are no leaks. Proper maintenance not only ensures stable performance but also reduces the frequency of breakdowns and maintenance costs.

Utilize professional after sale service and technical support

Even with careful use and maintenance, problems may still arise with the HDPE blow molding machine. At this time, relying on professional after sale service and technical support is crucial. Choose manufacturers that provide comprehensive after sale services. These manufacturers have professional technical teams that can respond quickly to your problems. Whether it's through online consultation, phone support or on site maintenance, they can provide effective solutions in a timely manner. Take advantage of the manufacturer's technical resources. Participate in training courses provided by the manufacturer to improve the operator's skills and understanding of the HDPE blow molding machine. This enables operators to handle minor problems independently and use the machine more properly. Maintain close communication with the manufacturer. Share the machine's operation status and production feedback with them regularly. The manufacturer can provide targeted suggestions and optimization plans based on this information, helping you better maintain the stable performance of the HDPE blow molding machine. With the support of professional after sale service, you can use the machine with more confidence.